Bias 1: PLC-IoT is an outdated, low technology

1. What exactly is PLC-IoT?

- The full name of PLC is Power Line Communication, that is, power line carrier communication. As the name suggests, it is data transmission on traditional low-voltage wires. It can be divided into low-speed mode, medium-speed mode and high-speed mode in terms of speed.

- Usually "power cat" refers to the high-speed mode of PLC communication technology (HomePlug/G.hn), which is mainly used for broadband Internet access in the home, while PLC-IoT belongs to the medium-speed mode, mainly for the massive device access scenarios of the Internet of Things , which is different from the "power cat" in terms of communication performance, bandwidth, maximum number of network nodes, and network structure.

- The IEEE 1901.1 standard was established in the IEEE Alliance in 2016 and officially released in 2018. It is the latest medium-speed PLC communication technology.

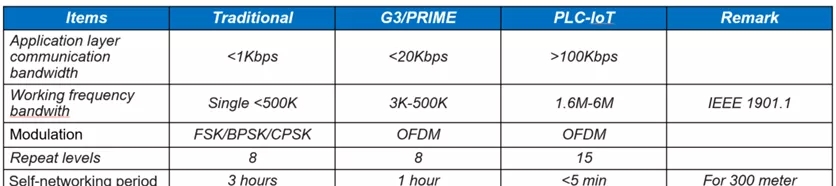

- Compare as follows:

Prejudice 2: PLC-IoT has poor performance as a whole-house intelligence, and all kinds of interference are large

1. Advanced PLC-IoT technology design and high reliability

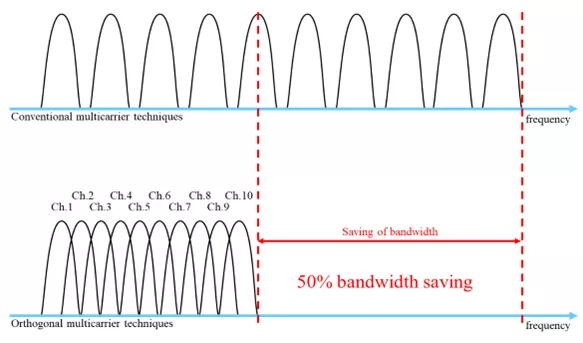

- PLC-IoT adopts OFDM modulation technology, the carriers are orthogonal, and the spectrum utilization rate is theoretically close to the Nyquist limit, saving 50% of the bandwidth compared to the traditional FDM system.

- PLC IoT adopts time-frequency diversity technology, which is more resistant to attenuation and noise

• The original data is backed up in the two dimensions of time and frequency, which is more resistant to attenuation and noise.

• Taking 4 copies as an example, if the 4 symbols carry all the information, the orange part represents the backup of the same information in the time and frequency dimensions. It can be seen that the data is backed up evenly in the time and frequency dimensions. Or the frequency information is damaged, other backup data can be used to restore the information. This technology is also specially used to combat the time-varying interference and frequency-selective attenuation of power lines.

- PLC-IoT frame structure design has stronger anti-attenuation and anti-interference ability

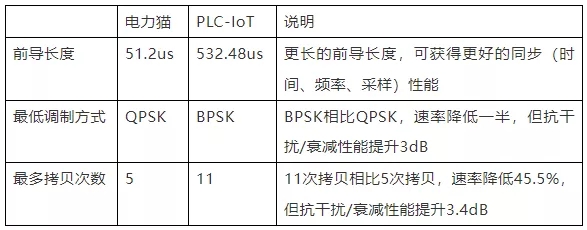

Compared with "Power Cat", PLC-IoT has enhanced frame structure (preamble), modulation, and copy mode, and exchanges the communication rate for more reliable communication performance, which is in line with the high reliability and low traffic communication characteristics of the Internet of Things.

2. PLC-IoT is based on the evolution of HPLC technology with massive applications, which has actually proved to be highly reliable

- The HPLC standard was established in the power grid in 2014, and the industry standard (Q/GDW 11612-2016) was officially released in 2017, and began to be commercialized on a large scale. Up to now, the power grid has operated 250 million devices, and HiSilicon has a share of nearly 200 million.

- PLC IoT is a key technology based on HPLC, which derives the IoT communication standard for the industry market, namely IEEE1901.1.

3. Unique anti-noise technology: noise library, targeted processing

- The complexity of the PLC channel is largely reflected in its different noise characteristics in different scenarios, with strong energy and rapid changes. Therefore, anti-noise technology plays an important role in PLC-IoT solutions and is one of the core technologies for physical layer communication performance assurance.

- Based on this, the algorithm design and denoising scheme form a system, which runs through each module:

• In the time domain: Design an effective pulse noise detection and elimination algorithm, perform real-time denoising according to the difference in pulse period, duty cycle, and peak-to-average ratio, which can cope with microsecond-level changes in time-domain noise.

• In the frequency domain: Design an effective narrowband noise detection and elimination algorithm. According to the power spectral density distribution of noise at different frequency points, a variety of detection processing methods are adopted to detect and eliminate narrowband noise.

• For out-of-band noise in communication, adopt the combination of board-level filter, built-in analog filter and digital filter to adaptively eliminate out-of-band noise.

- HiSilicon has built a comprehensive power line noise database, collects power line data from all over the world for simulation modeling, and replays it to the laboratory power line environment for communication testing and optimization of anti-manufacturing algorithms.

- Tested in a full-scenario environmental laboratory, it has been running stably for more than 4 years in high temperature, high humidity, high altitude, extreme cold, and extreme drought.

Bias 3: What is the best way to connect whole-house intelligence?

1. Compared with the existing Zigbee technology, PLC-IoT has obvious advantages

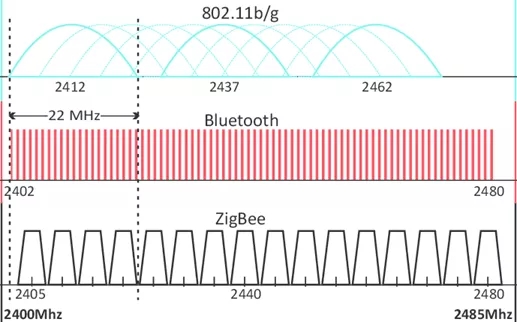

In the control scene of smart home, the main wireless technology currently used is Zigbee, which is a low-speed and short-distance wireless network protocol. The main advantages are low speed, low power consumption, low cost, and support for a large number of online nodes; , the effective range is small, and the anti-interference performance is poor.

The Zigbee solution is easily blocked by strong blocking and signal interference in the unlicensed spectrum. To obtain a good lighting effect, once there are many lights in the home, the control in the scene mode will be very unstable.

The PLC-IoT control bus greatly solves the above problems. Through the localized whole-house intelligent host, PLC realizes the pioneering work of "connecting with electricity", which can support the transmission distance of 2,000 meters and easily cover large houses up to 500 square meters. The communication success rate of up to 384 connected devices is as high as 99.99%, which is more stable.

- The PLC is not blocked by the wall, and the wireless connection technology has weak wall penetration ability

- Zigbee technology has serious co-channel interference and weak stability under 2.4G, and multi-point simultaneous operation is prone to network congestion

- Comparing PLC and ZigBee, the advantages are clear at a glance

Prejudice 4: PLC-IoT whole-house smart deployment is inconvenient

1. PLC-IoT compared to existing wired technology KNX

KNX wiring is used for intelligent control of the whole house. In the case of lighting power supply, an additional control wire needs to be pulled, resulting in a large host and complicated wiring. Professional design, installation, and post-maintenance are required, so the cost is high.

- PLC-IoT connection is stable, reliable and powerful

- PLC-IoT is cost-effective and easy to deploy

- PLC-IoT makes the whole process of pre-installation "simplified"

• Design stage: PLC equipment is designed in the same or multiple circuit loops as required (simplified design).

• Construction stage: The electrician completes the physical installation without the participation of the designer; no software configuration is required, the PLC equipment is automatically networked, and the network is zero-distributed.

• Acceptance stage: The electrician accepts the design according to the scene and circuit, without the participation of the designer.

• Operation and maintenance stage: The equipment is directly replaced, and the network is automatically formed after power-on. There is no need to check the interference of other wireless equipment on the PLC equipment, and there is no need for designers to participate.

2. Unique PLC network technology

- Automatic and fast networking, instant messaging, all roads lead to Rome

CCO: (Concentrator) Master Node Module

STA: (Station) child node module

PCO: (Proxy Coordinator) proxy node

• Flexible networking mode: ①Tree networking, CCO is the main node of the network, STA is the sub-node of the network, if STA becomes a proxy site, it is called PCO; all STAs initiate network access requests to the CCO, and the CCO can only join the network after confirmation. PLC communication can be carried out immediately after establishment; ②Mesh networking: There is no CCO, each STA is also a PCO, and the STA communicates directly with the STA.

• Automatic and fast networking mode: Automatic and fast networking, 500-node, 2-layer network scenario completes networking within 10s of initial power-on, fast communication; single-node power-on millisecond-level network access, suitable for single-node device power-on, replacement, plug-in Dial and other scenarios; support dynamic routing, multi-path addressing.